Using its Lost Core Resin Transfer Molding (LCRTM) system, Wichita, Kan.-based Fiber Dynamics Inc. manufactured the main landing gear strut for the Predator B MQ-9 Reaper.Using its Lost Core Resin Transfer Molding (LCRTM) system, Wichita, Kan.-based Fiber Dynamics Inc. produces complex, hollow structures in a single molding operation. For the past 10 years, the company has used the process, developed in-house, to manufacture the main landing gear strut for the Predator B MQ-9 Reaper unmanned aerial vehicle (UAV), produced by General Atomics Aeronautical Systems (San Diego, Calif.).

“Conventional prepreg processes were unable to economically provide the structural performance required, and metallic options would typically weigh and cost more,” explains Fiber Dynamics’ CEO Darrin Teeter. “In comparison, our LCRTM system reduces weight and cost, and improves structural integrity through a unitized structure.”

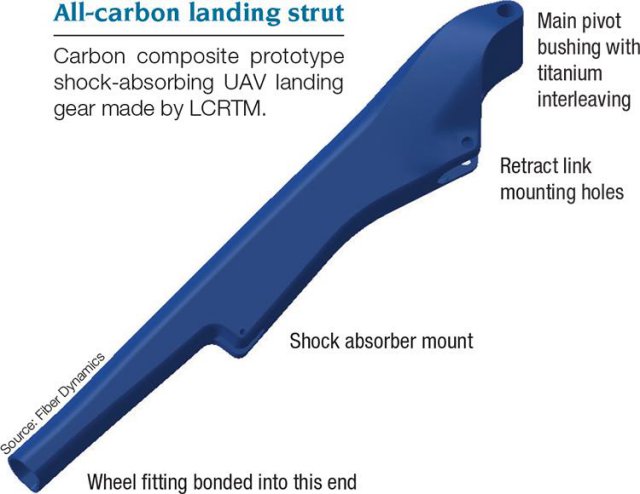

More than 600 of these struts — functionally, hollow leaf springs — have been made using S-2 Glass fiber from AGY (Aiken, S.C.) with a carbon fiber center stiffener (see photo above). Now, Fiber Dynamics is developing a prototype strut for another as yet unidentified UAV (image at right). “This one uses a shock absorber to cushion the landing instead of the spring action of the strut itself,” Teeter says. To meet the higher stiffness and load requirements of this design, IM7 unidirectional carbon fiber from Hexcel (Stamford, Conn.), aligned in the primary load-bearing direction (longitudinal), is woven together with a plain-weave carbon fiber fabric, to Fiber Dynamics’ specifications, by Fabric Development Inc.(Quakertown, Pa.).

More than 600 of these struts — functionally, hollow leaf springs — have been made using S-2 Glass fiber from AGY (Aiken, S.C.) with a carbon fiber center stiffener (see photo above). Now, Fiber Dynamics is developing a prototype strut for another as yet unidentified UAV (image at right). “This one uses a shock absorber to cushion the landing instead of the spring action of the strut itself,” Teeter says. To meet the higher stiffness and load requirements of this design, IM7 unidirectional carbon fiber from Hexcel (Stamford, Conn.), aligned in the primary load-bearing direction (longitudinal), is woven together with a plain-weave carbon fiber fabric, to Fiber Dynamics’ specifications, by Fabric Development Inc.(Quakertown, Pa.).

Fiber Dynamics begins the manufacturing process by casting the core from its proprietary Thermocore material. Tailored for low-melt viscosity and minimal thermal expansion, the material “behaves like a thermoplastic,” Teeter says. The cast core is then machined to the exact shape of the inside surface of the part’s hollow cavity. It serves as a male mold for formation for the carbon preform and as a sacrificial mandrel during molding.

Dry fabric for the preform is cut into preprogrammed ply patterns on a CNC cutting system from Eastman Machine Co. (Buffalo, N.Y.), and the plies are layed up directly on the core mandrel — along with doublers and fittings — using customer-approved epoxy tackifiers. Titanium doublers are interleaved with the carbon fabric around the primary load-bearing bushing, which is molded-in and hinged to enable landing gear deployment and retraction.

“The titanium plates fit very tightly against the bushing to help mitigate and transfer the high loads into the laminate — especially the high impact loads created on landing the more than 4,000 lb [1,814 kg] UAV,” Teeter says. The dry preform is then consolidated, either by vacuum or mechanical compression. “We are able to compress it to the net shape of the mold cavity,” Teeter explains, noting that the preform volume, then, is “60 percent fiber, and 40 percent air,” a match for the part’s expected 60/40 fiber/resin ratio.

The net-shape preform and core are enclosed in the female closed mold that defines the part’s outer geometry, and then it is infused with an unnamed epoxy resin system supplied by Momentive Specialty Chemicals (Columbus, Ohio), using standard RTM techniques. The part is cured at a temperature below the melting temperature of the Thermocore mandrel. After demolding, the part is CNC-trimmed and holes are drilled for fittings and fasteners, which, synergistically, provide drainage paths for the mandrel when the part is postcured at a proprietary temperature that melts out the Thermocore. After postcure, the part is cleaned to remove residual mandrel material.

Still in the test phase, Fiber Dynamic’s carbon composite LCRTM landing gear is proving its ability to absorb the landing loads imposed by the UAV. “Based on test results, we expect the landing gear leg to be fully implemented when the UAV begins production,” Teeter says. When that will be has not yet been determined.

Teeter points out that the UAV market provides opportunities to try new processes and produce prototypes that would be much more difficult to attempt on a manned aircraft. However, he adds, “that will probably change as UAVs start entering public air space.” A test program is underway to safely implement integration of unmanned aircraft systems into U.S. airspace in 2015.

Source: Composites World