There are large companies with big plans to offer services based on drone fleets, and they are all eager to get beyond a significant operating challenge: the flight time of commercial drones is constrained by limited battery capacity. One way to address the issue is with more efficient and flexible re-charging solutions.

And that explains the keen interest in WiBotic, which designs and manufactures solutions for charging drone and robot batteries. The 4-year-old startup recently secured $5.7 million in Series A funding.

WiBotic offers wireless charging and power optimization solutions for the aerial, mobile, marine, and industrial robot market. Its Adaptive Matching technology offers a new method for inductive power transfer that the company says provides the power levels needed for drones and other flying devices.

Such optimization solutions provide detailed monitoring of battery charge parameters through software libraries. Combined with the strategic deployment of wireless charging hardware, these software features are designed to optimize the uptime of drones.

WiBotic wireless charging solutions also handle recharge scheduling; they are designed to clear the way for multiple robots to charge from the same transmitter at different times.

Wireless power transfer (WPT)

The use of electromagnetic fields as a source of electricity dates back to the late nineteenth century when Nikola Tesla first demonstrated the transmission of electricity without wires. The wireless methodology is well known, but the design of transmitters, their location, maximizing efficiency, and the need for a validated behavior of the entire system represent a complex challenge that requires specific skills and the use of advanced tools such as numerical simulation. The methods used by the most common WPT systems are inductive coupling or MRI, each of which has strengths and weaknesses.

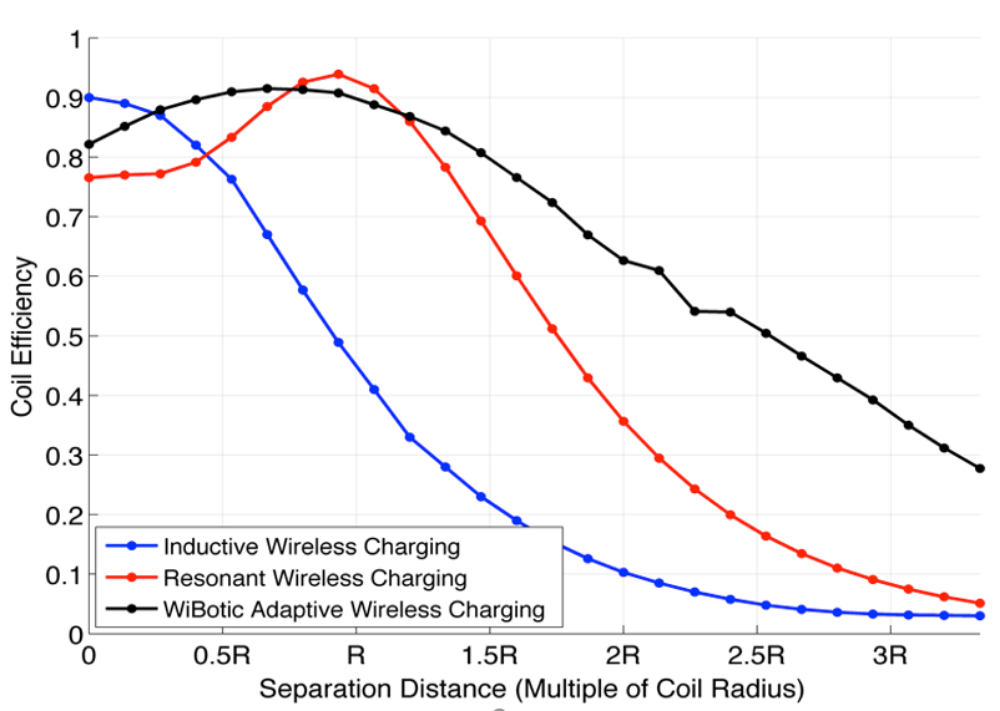

The most common of the methods is the inductive one — as typically found in consumer devices. Unfortunately, they are only efficient when the antennas are extremely close together. Robots and drones cannot position themselves precisely enough to make sure that the inductive systems provide a reliable charge.

Magnetic resonance technology is the latest technology that offers much more flexibility in positioning. However, typical resonance systems have a special area where maximum efficiency can be exploited. If the robot stops briefly or is off-center, however, efficiency is reduced, and charging times increase.

WiBotic technology is based on the strengths of both inductive and resonant systems as it incorporates the best of both.

“Our patented Adaptive Matching system constantly monitors relative antenna position and dynamically adjusts both hardware and firmware parameters to maintain maximum efficiency — delivering reliable charging, at high power levels, and across several centimeters of vertical, horizontal and angular offset,” said Ben Waters, WiBotic’s CEO.

Software algorithm

Knowing when to recharge the drone when the battery is low is an important feature to assess downtime. Different robots will have different types of battery chemistry, voltages, and current. WiBotic’s energy optimization software is able to evaluate the robots coming in for a charge and determine the best way to charge them.

The Wibotic firmware allows robot operators to monitor and set the desired charging parameters. The onboard brain allows the drone to directly access the onboard charger to perform the same functions. The architecture of the structured wireless charging network allows robots to stay charged, minimizing downtime, and reducing the overall cost of robot fleets.

“A lot of our innovation for robotics comes on the output of the RF amplifier on the transmitter, and then on the receiver side, the input to the rectifier, that’s where we are able to dynamically tune our systems impedance to make sure that we are maximizing our power transfer by keeping the source and load impedances on both sides of the air-core transformer matched. We’re dynamically tuning and sensing things very quickly in real-time to accommodate movements or disruptions or changes as they happen in the system,” said Waters.

Wibotic system architecture

The wireless charging station for drones is a square platform (3 feet by 3 feet for the standard pad) consisting of an “intelligent” induction plate that, during the landing of the drone, determines the type of batteries supplied to the aircraft, thus establishing the correct charging parameters.

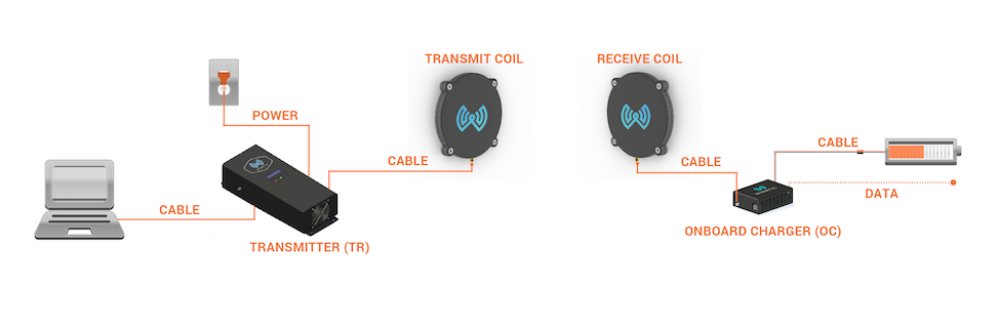

All WiBotic wireless charging systems consist of four primary hardware components: transmitter unit, transmitter antenna coil, on-board charging unit, receive antenna coil.

The transmitting unit generates a high-frequency wireless power signal through the AC source. The signal travels through an SMA coaxial cable to the transmitting antenna coil, where it generates both electric and magnetic fields. The coil can be mounted in any orientation according to the drone’s runway.

The transmitter unit recognizes any incoming robot equipped with an on-board charging unit and receiver antenna coil and is automatically activated to provide the right amount of energy. The collection coil feeds energy to the onboard charger circuit. The on-board charger converts the signal back to DC voltage and controls the battery charging functions to safely charge a wide range of batteries.

“The processor that we use is an ARM-based STM32 microcontroller. We use a complex state machine along with dynamic control algorithms running locally on the processor. Together, these determine how outputs should be changed in response to incoming signals. If you’re sending several hundred watts of power and you change the wrong parameter, you might very easily disrupt the system instead of benefit the system. So being able to determine what to do to react to changing conditions in real-time is a big part of our system. And when you need to do things quickly and you don’t have a huge amount of compute capability, it needs to be fairly well optimized in both software and hardware. Utilizing a GaN technology semiconductor in our RF amplifier was integral to optimizing how the hardware performs,” said Alex Huttunen, lead software engineer for the company.

GaN technology offers the wireless autonomous charging that these conditions require by operating at a high switching frequency with maximum efficiency. In collaboration with GaN Systems Inc., WiBotic integrates GaN devices to provide the power levels and antenna range requirements that both drones and robots require. In addition, the Vicor 48V VI Chip PRM Regulator PRM powers the transmitter on board the WiBotic TR-110 wireless charging station, which wirelessly powers the robot/drone on-board receiver. The PRM accepts 48V from an AC-DC power supply and the output voltage is adaptively controlled and cut off from about 20 – 55V.

“We’re primarily focused on robotics, automation, and industrial devices. But, we’re very excited about wireless charging growing in many industries; its adoption is increasing in mobile phones and expanding to many other industries as well, said Matt Carlson, WiBotic’s VP of Business Development. He continued “we’re developing more algorithms that would align with AI and machine learning-based on historical trends and applying them towards the future performance of an analysis, specifically around battery charging.”

With the wireless drone re-charging system, the entire recharging process can be monitored and controlled remotely using cloud-based software, APIs, and tools to ensure that drones reload as quickly as possible when needed or more slowly when flight planning is not massive.

WiBotic already is working with an array of customers that include Waypoint Robotics, Clearpath Robotics and Aero Corp.

“We have customers in about 13 countries across five continents, from drones to mobile robots to unique battery-powered IoT applications.” Waters said.

The fresh round of funding will help the company advance its technology, expand its sales team and accelerate its growth to answer customer demand.

“We need to make sure that, as infrastructure in this robotics market, we’re one step ahead of our customers,” Waters explained. “They need to be able to have confidence in our product and our team and our company to move forward with an important piece of a robotic ecosystem.”