MicroLink Devices, Inc. announced that it has developed a lightweight, flexible, high-efficiency solar sheet suitable for powering small electrical equipment and extending flight times of small unmanned systems.

MicroLink Devices, Inc. announced that it has developed a lightweight, flexible, high-efficiency solar sheet suitable for powering small electrical equipment and extending flight times of small unmanned systems.

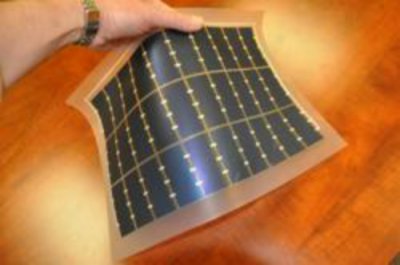

The sheet has a conversion efficiency of 29%, generates up to 9.25 watts in a 320 square centimeter active area, and weighs 230 grams per square meter. The sheet is highly flexible and can be wrapped around a cylinder a few inches in diameter without damage.

The solar sheet is enabled by MicroLink’s proprietary epitaxial lift-off (ELO) technology, in which a triple-junction solar cell is removed from the semiconductor wafer on which it is grown. The solar cell is mounted on a metal sheet, which provides mechanical support to the thin, brittle solar cell material. The efficiency of the 20-cm2 solar cell, which resembles a sheet of thin metal foil, is up to 32.2%. The ELO process permits the solar cell to be removed from the semiconductor wafer without damaging the wafer, which can be reused multiple times. This enables a substantial reduction in the cost of the ELO solar cell compared with conventional triple-junction solar cells.

The solar sheet is enabled by MicroLink’s proprietary epitaxial lift-off (ELO) technology, in which a triple-junction solar cell is removed from the semiconductor wafer on which it is grown. The solar cell is mounted on a metal sheet, which provides mechanical support to the thin, brittle solar cell material. The efficiency of the 20-cm2 solar cell, which resembles a sheet of thin metal foil, is up to 32.2%. The ELO process permits the solar cell to be removed from the semiconductor wafer without damaging the wafer, which can be reused multiple times. This enables a substantial reduction in the cost of the ELO solar cell compared with conventional triple-junction solar cells.

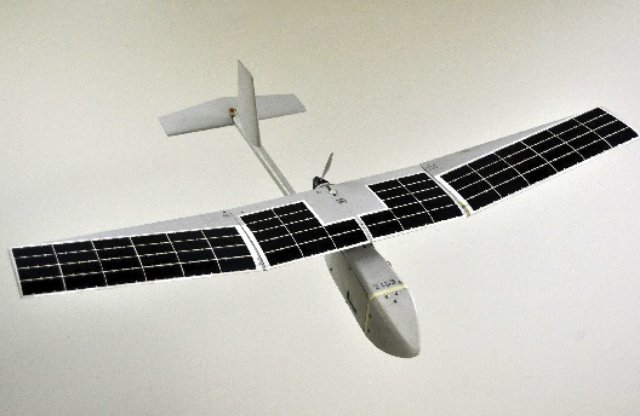

MicroLink is currently transitioning its solar sheets from research and development to practical applications. In a project funded by the US Air Force Research Laboratory, the solar sheets have been mounted on the wings of Raven unmanned aircraft systems (UAS), resulting in a doubling of the UAS endurance. In another project funded by the US Naval Research Laboratory, the solar sheets have been mounted on the backpack worn by a US Marine. The collected energy is used to charge a BB-2590 battery. The goal of the program is to reduce the weight of batteries carried by the Marine.

Dr. Noren Pan, the President and CEO of MicroLink Devices, said, “We are extremely proud to have developed this high-performance solar sheet. We know of no other device that offers a comparable performance in terms of efficiency and weight.”

Source: Press Release