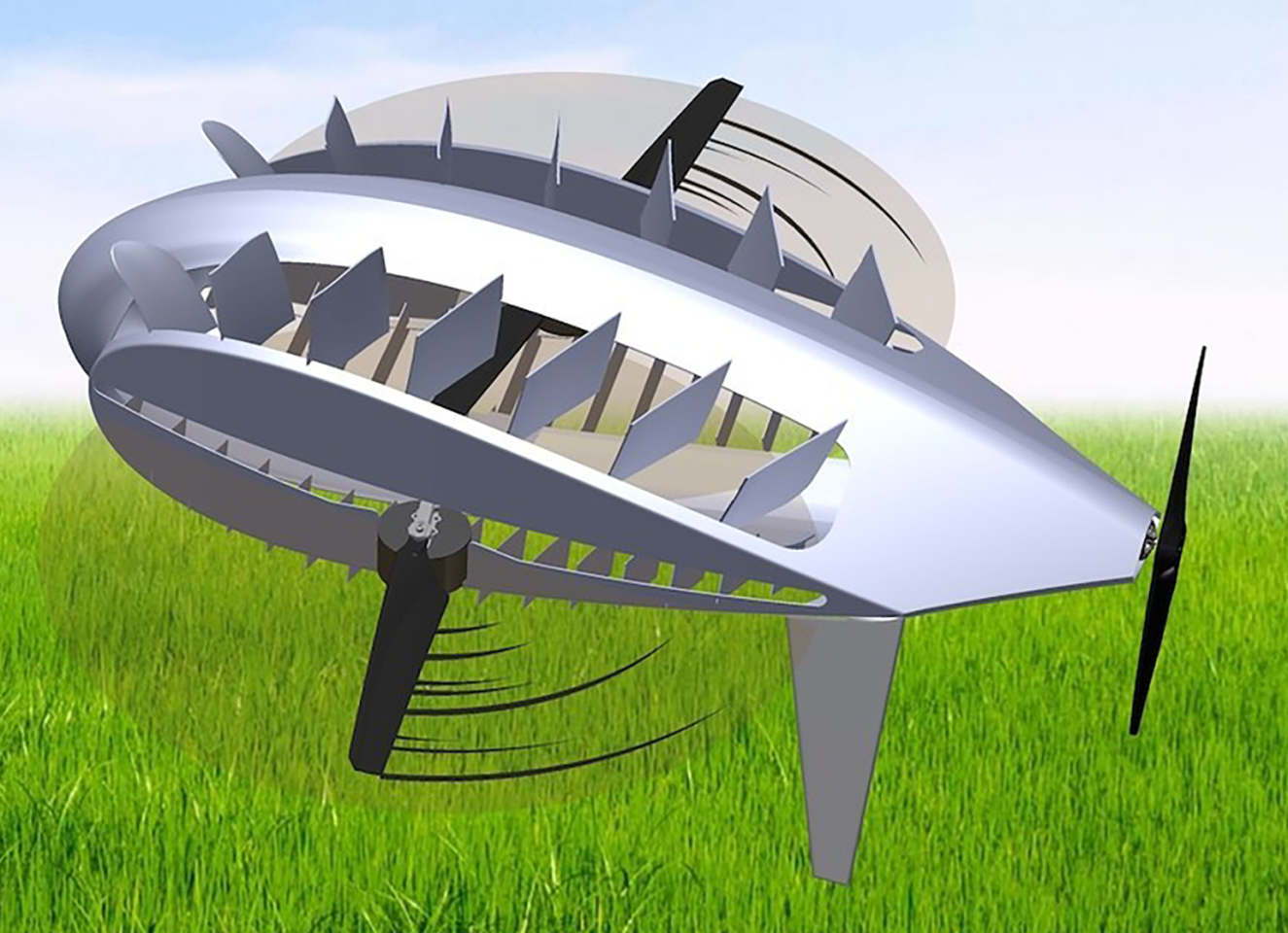

Blainjett‘s fascinating hemispheric rotor concept is a totally unique and left-field approach to VTOL flight. The company came up with the bones of the idea while working on the Horizon eVTOL hoverbike, and trying to solve the problem of how to generate lots of efficient vertical thrust without taking up large amounts of space or exposing bystanders to fast-spinning propellers.

Blainjett’s solution was to go with big, variable pitch rotors for efficiency, but to tuck the entire retreating half of the swept disc away under the bike’s bodywork. Using a split swashplate, adapted from the helicopter world, they devised a system that would immediately ramp the blade pitch down to fully horizontal every time it went into its slot in the bodywork, then ramp it back up to a positive lift pitch when it emerged on the other side.

That was on a hoverbike. Now, the company is designing a hemi-rotor, cruise-capable drone to take maximal advantage of the idea, and it adds a couple of interesting wrinkles to make things even more effective.

“If our lab testing continues on its current trajectory,” Zachary says in a new press release, “we believe our [hemi-rotor-configured] prototype will boast the most efficient hover and forward flight profile of any rotor-borne VTOL aircraft.”

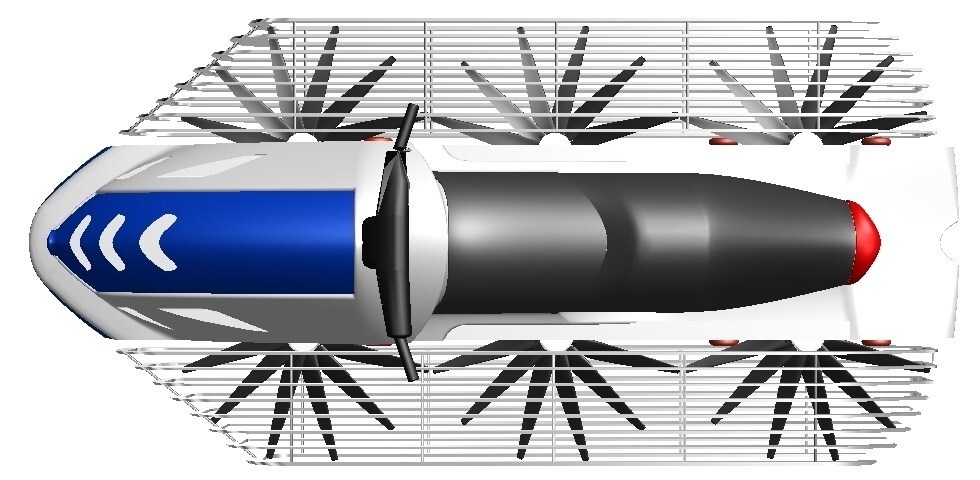

Them’s some fightin’ words, alright, but the new machine certainly appears to up the ante. It runs just two lift rotors, but they’re disproportionately huge compared to what you’d see on a typical drone, and they can presumably handle all the micro-corrections and nuances of VTOL flight thanks to their variable-pitch blades.

For VTOL and hover operations, the drone’s top and bottom bodywork opens up in a series of slats, exposing a greater percentage of the rotors’ swept area to airflow and deriving maximum lift. Then, as it begins to move forward under the power of a large rear pusher prop, these slats close up, and the lift rotors begin operating in hemi-rotor mode, flattening out as they pass through the bodywork and pitching back up when they’re out in the air.

At a certain airspeed, the lift rotors are able to stop altogether, pointed out to the sides, and begin acting as wings. The drone’s bodywork itself is designed to act as a wing as well when it’s closed, and the ability to change the pitch of the blades on the lift rotors lets them operate as control surfaces in cruise flight.

So what you’ve got is a vertical lift system with two enormous rotors instead of four or more much smaller ones, in a very compact ground footprint. If the air can move smoothly through the slats in the bodywork, I can see this being a super-efficient machine in VTOL and hover operations. And then in forward flight, you’ve got another sizeable propeller, a lift-generating body, and a uniquely tuneable set of wings that can be finely managed both in terms of blade pitch and their sweep angle relative to the body.

Blainjett says it’s built small-scale prototypes and tested them in different phases of flight, achieving results that validated its expected lift and drag profiles. The company has entered a partnership with Fenris Electric Systems to develop the complex and custom flight control systems it’ll need to operate all the bells and whistles on this bad boy.