3W International is participating in this year’s Xponential, formerly AUVSI, where it will introduce an expanded range of engines. Besides the previously exhibited Heavy Fuel (HF) engines, the German engine manufacturer will also exhibit a portion of its petrol engines as well as a complete engine unit.

3W International is participating in this year’s Xponential, formerly AUVSI, where it will introduce an expanded range of engines. Besides the previously exhibited Heavy Fuel (HF) engines, the German engine manufacturer will also exhibit a portion of its petrol engines as well as a complete engine unit.

In addition to the engines, the PowerVision GmbH Company uses an RPAS helicopter to show that 3W International’s engines can be used in more than just fixed-wing aircraft.

3W International is exhibiting a portion of its engines for the first time in 2016. This is due to strong demand from the civilian applications area. All engines from 3 HP to over 60 HP can be provided with both carburettor and alternatively with electronic injection. Fuel consumption can thereby be reduced due to more exact consideration of all of the operating parameters. The power density can be increased through better mixture treatment and the engine’s regulation can be better controlled at various engine powers. This is especially true during warm-up.

Moreover the team from 3W International analysed the last trade fair and the conclusion was clear: the market demands complete engine systems. ‘That means customers are increasingly looking for engines with all of the additional systems such as generators, starters, cooling jackets, engine mounts, and silencer systems’, confirms Karsten Schudt, managing director of 3W International GmbH. 3W International will exhibit a complete drive unit at the exhibit stand for illustrative purposes.

‘We deliver our engines ready for use to the customer. The engines are completely equipped and delivered with ECU, silencer, starter, generator, engine mount, and cooling jacket. The customer himself basically has to complete only three tasks: unpacking, installing, and taking wing’, explains Schudt. Here every drive unit is tailored to the customer’s desires and needs.

3W International is also introducing engines for hybrid applications in addition to the complete drive units. The hybrid drive has moved increasingly into the foreground in recent months. ‘Most of the inquiries here relate to the UAVs’ commercial or civilian use’, confirms Schudt. The internal-combustion engine takes on the most varied tasks in these cases. For one thing it can be used for vertical starts in which high performance is required depending on the application area. The internal-combustion engine is used in combination with a generator to supply power to the electrically driven rotors, which move the flight object after take-off. Furthermore the internal-combustion engine fills in when energy stored in the on-board batteries diminishes.

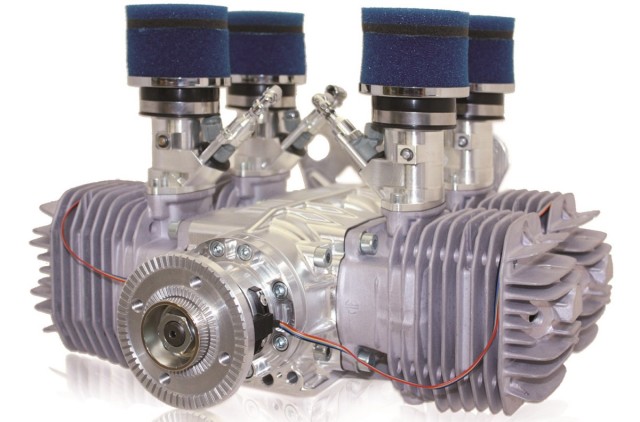

An additional exhibit completes 3W International’s exhibit stand. The customer PowerVision GmbH is exhibiting the DRAGONFLY DF M35 RAPS helicopter. PowerVision GmbH, with headquarters in the immediate vicinity of Frankfurt a.M., Germany, is an internationally active company specializing in the development, production, and sales of RPAS helicopters. The DRAGONFLY DF M35 is equipped with the 2-cylinder, 14.5 kW, 3W-170 XiB2 TS CS flat engine with double ignition from 3W International.

3W International is located in hall 1, booth 567.

*****

With more than 30 years of experience in designing, manufacturing and testing 2-stroke engines, 3W International GmbH has developed and patented the newest generation of Heavy Fuel (HF) engines for the Unmanned Aerial Vehicle (UAV) industry.

The quality of 3W-engines consists of several factors. Technical expertise, long-term experience, tradition and state-of-the-art production are the reasons for one of the highest qualities in the industry. 3W disclaims manufacturing abroad so customers can be sure every engine is German quality.

From R&D, prototyping, purchasing, manufacturing, and calibration to on-time delivery, 3W guarantees constant, permanent quality control. Every manufacturing step is traceable. The employees are personally responsible for fulfilling 3W quality standards. Component suppliers and partners share those standards and guarantee these quality requirements.

Source: Press Release