Skyqraft, a data-driven infrastructure inspection company from Sweden, was granted BVLOS operation permission for the Vertical Technologies DeltaQuad VTOL UAV, to inspect a large portion of the Swedish power grid.

Fully Autonomous

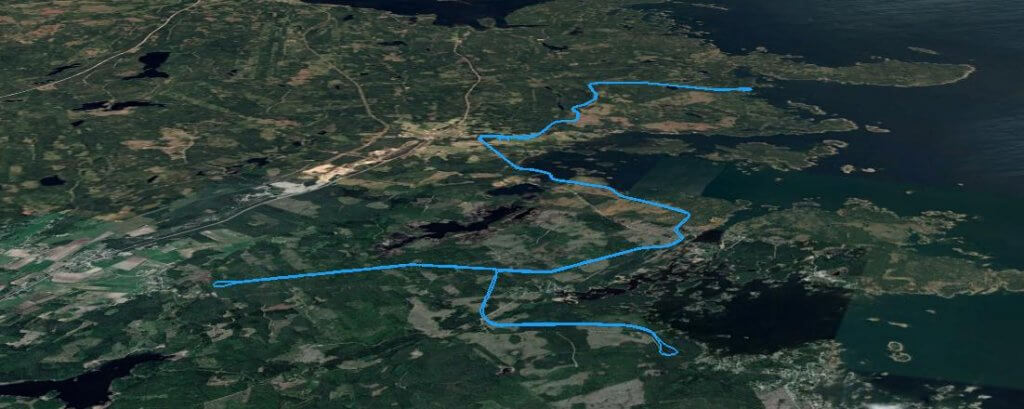

Flying fully autonomous from takeoff to landing, using long-range radio transmission combined with LTE based video and control links, Skyqraft was able to perform multiple BVLOS missions gathering high-resolution images for over 1,000 KM of powerlines. The resulting data is used for early indicators of failures to the powerlines, isolators, and towers.

The missions are planned to follow the powerlines at a safe altitude using automatic terrain following. The onboard camera is automatically triggered to record high-resolution photographs of the selected path while the operator receives live video and keeps a control link over long distances. Using ADS-B transponder receivers the pilot is made aware of any aviation up to 100 km away.

Beyond Visual Line Of Sight Waiver

A DeltaQuad Pro #MAP was initially trialed in Visual Line Of Sight (VLOS) and Extended Visual Line Of Sight (EVLOS). The success of these trials, combined with the advanced failsafe features and a redundant flight system, led the Swedish authorities to issue Skyqraft an additional waiver for the DeltaQuad to fly extended-range missions and to cross populated areas.

With the waiver secured, and after several BVLOS missions over scarcely populated areas, the DeltaQuad was instructed to perform 2 missions crossing the city of Gävle autonomously covering 90KM of powerlines. A significant step forward as this was the first official autonomous BVLOS flight of a fixed-wing UAV over a Swedish city.

To date, Skyqraft has logged over 30 flight-hours BVLOS and inspected more than a thousand kilometers of powerlines.

Machine Learning fault detection

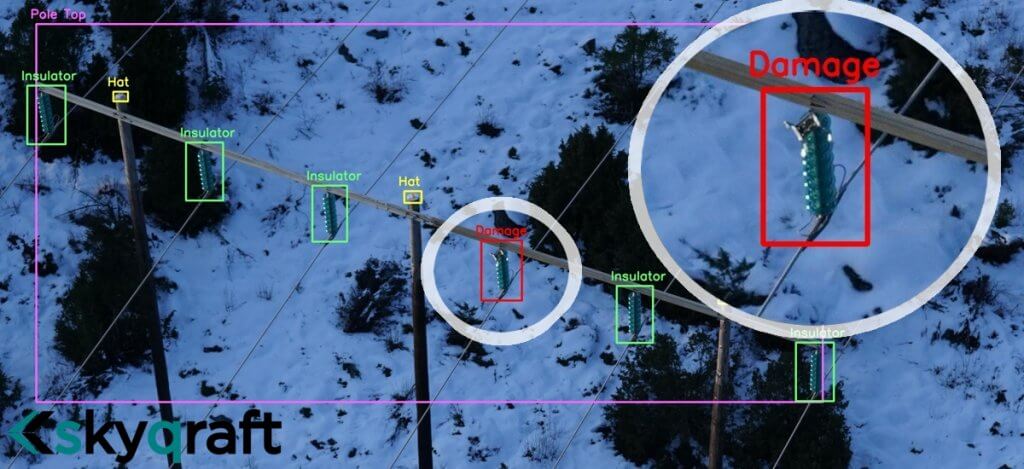

Using the latest technologies in the field of machine learning, the resulting data sets are automatically analyzed and, faults to any of the core components are flagged for manual review.

Every confirmed fault is added to a daily report combined with imagery and exact geographic location. The reports are dispatched to the designated maintenance teams who in most cases can act within 24 hours of detection.

Source: Press Release